By using minerals in bio-geochemical technology, we can influence the interaction between microbes and metals, to improve environmental management.

The health of soil and water can be managed through the interaction between microbes and metals, using minerals in bio-geochemical technology. Microbes (bacteria, fungi and algae) influence metal concentrations when deteriorating rock and minerals during bio-weathering and when forming, directly or indirectly, minerals during bio-mineralization (Gadd, 2010).

This interaction between minerals, microbes and metals determines the availability of life sustaining resources and life-threatening toxins that regulate the natural habitat of the critical zone or biosphere; the near-surface environment of rock, soil, water and air, home to living organisms.

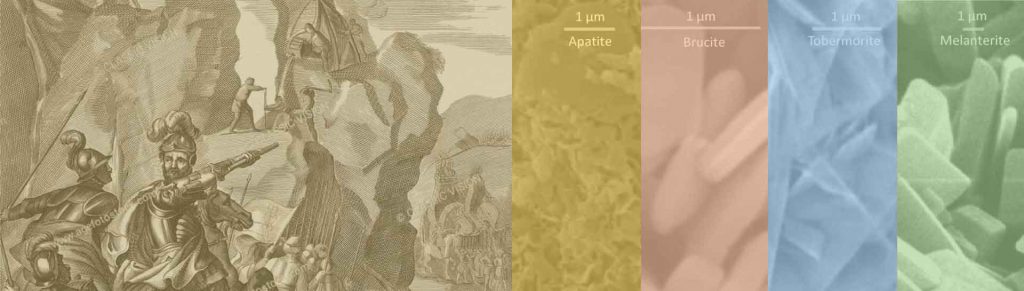

Microbes concentrate the essential nutrients from mineral surfaces (Vaughan et al, 2002); i.e. carbon, hydrogen, oxygen, nitrogen, phosphorus and sulfur that form 95% of the biomass and other elements with essential biochemical and structural functions such as K, Ca, Mg, B, Cl, Fe, Mn, Zn, Cu, Mo, Ni, Co, Se, Na and Si. Microbes and minerals also control the concentrations and bio-availability of thirteen trace metals and metalloids that are considered priority pollutants i.e. Ag, As, Be, Cd, Cr, Cu, Hg, Ni, Pb, Sb, Se, Tl and Zn (Sparks, 2005).

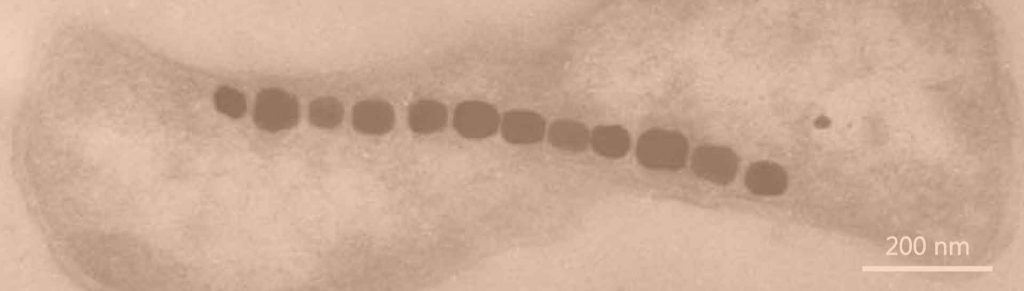

Many examples show how microbes interacting with metals may operate in environmental management. For instance, microbial metal mobilization through bio-leaching can be used for metal recovery, recycling and bioremediation of mineral waste and contaminated soil (White et al, 1998). Microbes can be used to immobilize metals by bio-precipitation, for decrease of toxic concentration in bio-available phases. Reduced metal(loid)s like Se(0), Cr(III), Tc(IV) and U(IV) form insoluble precipitates through reduction in anaerobic processes. Single-oxidation-state metals are immobilized during precipitation with biologically produced sulfide and phosphate. Immobilization through microbial biosorption occurs by physico-chemical binding of metals on dead and living walls of microscopically small cells that expose a very high surface per weight to the metal containing solution. Biominerals such as microbial nano crystals of magnetic iron oxides precipitated by magnetotactic bacteria can be used for sorption of metals and their recovery from solution by magnetic separation.

For practical use of microbes and minerals in environmental management we have to ask: How can microbes manage metals better with minerals in biogeochemical technology?